RHINO update

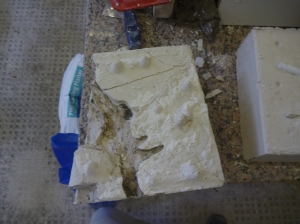

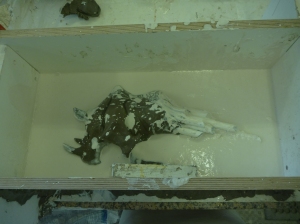

last layer for the rhino moulding

finished, remind myself the screw could not be inside, now the wood board could not separate…is not good for next step…e.g. drying and opening of mould.

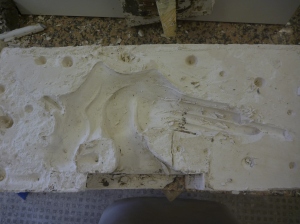

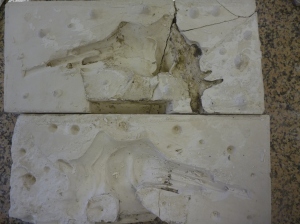

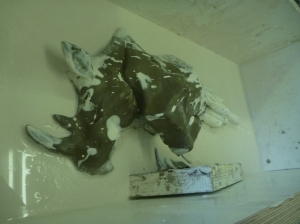

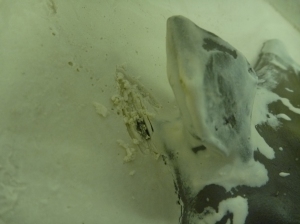

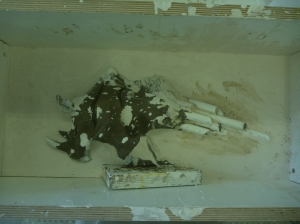

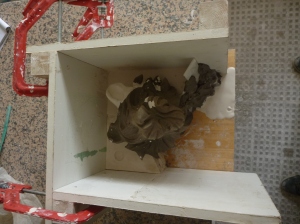

open it!

the dividing not very successful, hope it do not affect the casting so much

the lower piece, bottom left corner not firm and hard enough due to not mixing well of plaster….to be careful of washing

———————————————————————————————————————————————————

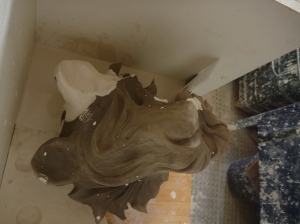

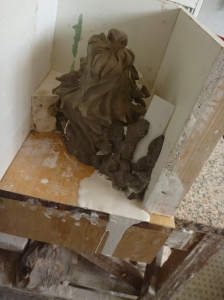

ORANGUTAN update

starting from wooden frame and wire to form the basic structure.

putting the clay on

after 2-3 nights…keep editing the….this model is difficult in balancing, and I want to make a good form with my style as well….so finally finished

now go for moulding, something to hold his back so that it maintain “floating” on the plaster

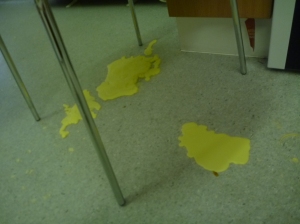

as the form is complicated…leaking always happen

this is what I said “floating”

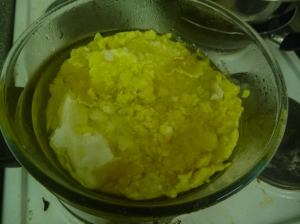

the mixing of plaster should be in quick and accurate amount…CONCENTRATE

finally I divided the mould into 7 pieces, and the rhino one just 3

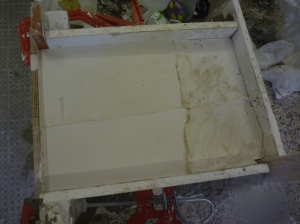

all wooden board removed for opening

————————————————————————————————————————————————————————

TIGER update

same…begin with wood and wire

clay on…this one ….difficult on standing

rough shape

the back…top view…I love the shape very much….a bit similar to my toy (battlecat from he-man)

almost finish, the gain or pattern will be sculpt after casting…..since those pattern will further make the sculpture weak…crack….and adding difficulty to the moulding …….and….one of the reason is every tiger’s pattern are individual….like fingerprints of human…so sculpt it out would be fun!

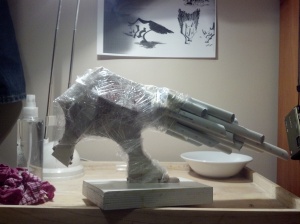

keeping it wet by plastic and wet towel

bring to uni and start moulding

the eyes take me so long for crafting, editting and crafting back and for….

the hand’s are cracked and brokennnnnnn! this one is too challenging, coz I do not have a stand for it….how to make it floats on plaster?!

finally start….remember to spray oil, on both the clay surface and plaster dividing, is really useful!!!

to be continued~