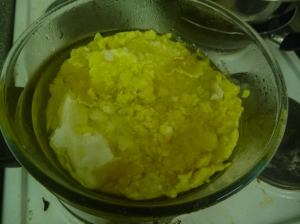

Here’s the clay model for the rhino, I will make a 3-piece-plaster mould, I am quite satisfy with the result, when comparing to the sketch and design, it’s almost the same. At the same time, I added some gain/ stroke?! to the sculpture, that’s inspired by the cracking dry skin from rhino itself. I twist a bit and make it like the tiger style…..so that’s my style!

last time stopped here, almost the shape came out, just need to modify the surface and add the other leg

starting the surface fine tune, add the other leg the the same time.

here I adding the grain from the tube in the back

for eyes, nose…I keep using the same style to present them

here we could see the grain clearly, however this version is a bit too much and distracting the whole art piece…it dominated.

so I simplified it a bit~

final work, tomorrow will bring back to college for mould making

————————————————————————————————————————————–

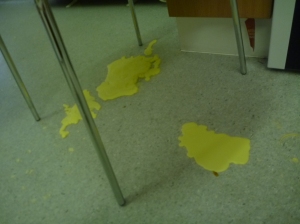

For lipstick collection, there are some responses from HK friends and UK friends, but I found there would be a lot more needed, and therefore I google ” UK makeup artist / expert” I emailed and Facebook messaged many (10 pages search of google). Hope there are more donated by them.

And, Some already being posted to me….hope my project really bring the message to my friends.

————————————————————————————————————————————–

and thinking of elephant….the 4 sketches before….not yet perfect….so keep sketching: