continue~

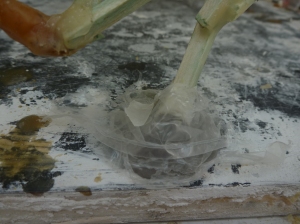

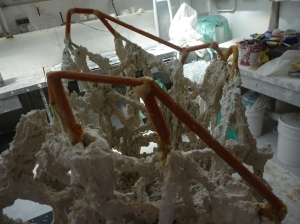

soft wax used to make the joins fatter, but the main linkage cannot rely on that.

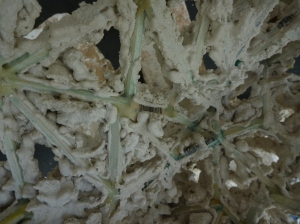

straws are used as other method of runners

little “worm-shape” wax as runner as well. since too much and close runners will may the grog crack….and damage the mold

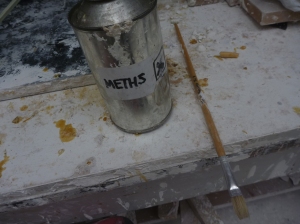

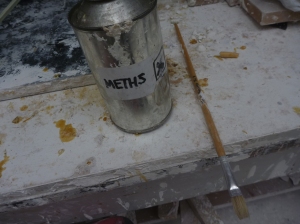

meths will be spread on the wax before painting a layer of grog on it.

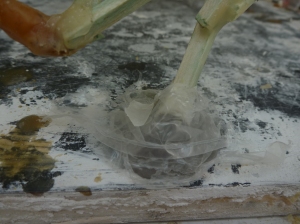

clay was used to detach the whole model, or it will stick on the broad.

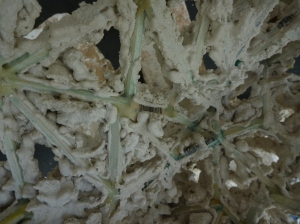

fine grog ( fine ceramics : paster is 2:1) painted on.

risers added afterwards (similar to runners), but runners is for liquid metal running while risers are for air go through. Without that, metal cannot go through properly.

grog wall making, because the mold will be inverted afterwards, wall between cup and risers was to ensure enough support.

grog wall making, because the mold will be inverted afterwards, wall between cup and risers was to ensure enough support.

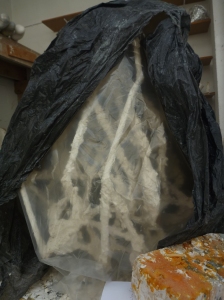

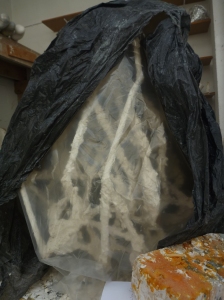

plastic bag for remaining humidity

inverted….since many inner surfaces could not be reached by fine grog

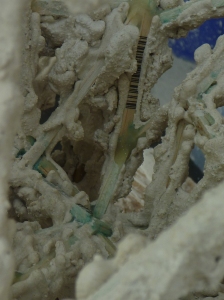

almost finish….adding extra risers

paint it together with grog

using flat metal to surround it, clays on the bottom avoiding grog leaks. recycled grog are used to cover the whole object

lifting for fire

final check for nothing blocking the risers

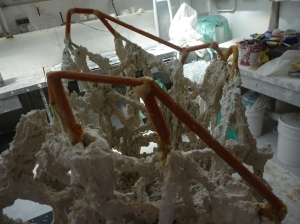

after firing, the mold is fragile, we have to use paster with net (3 layers) to hold it.

net rope with paster

metal bar also for enhancing the structure

o….my mold is full of smoke…why?

Becky using vacuum cleaner to check the risers

metal pouring

after one day, we dig it out

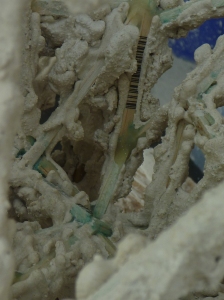

the smoke is because of some wood not burn out yet, some turned into charcoal….that’s also means that the mold is not perfect and some parts could not be reached by liquid metal

final outcome……less part can be cast, only the joins and some bottom parts. It is because 1) joints are fatter. 2) mold is too big, heat cannot reach inside well…..that’s why some wood just turn to charcoal.

during the interim show, Michael suggested me to use wax for the original model so that it melts easier and won’t turn to charcoal. On the other hand, try to use the technique named “ceramic shell” for casting. will search it out!